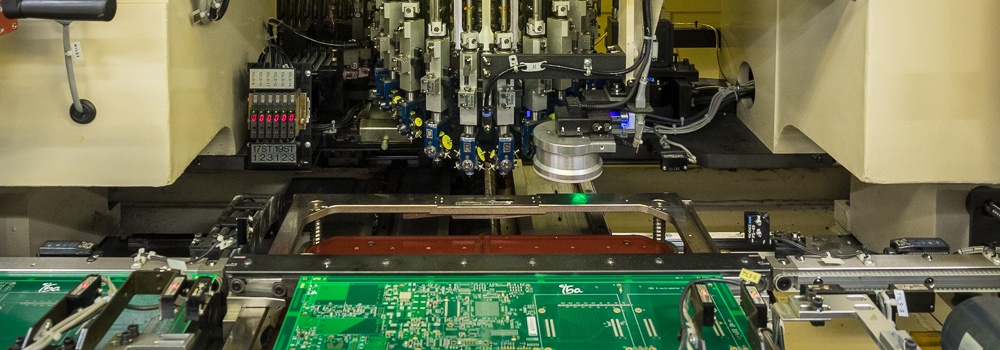

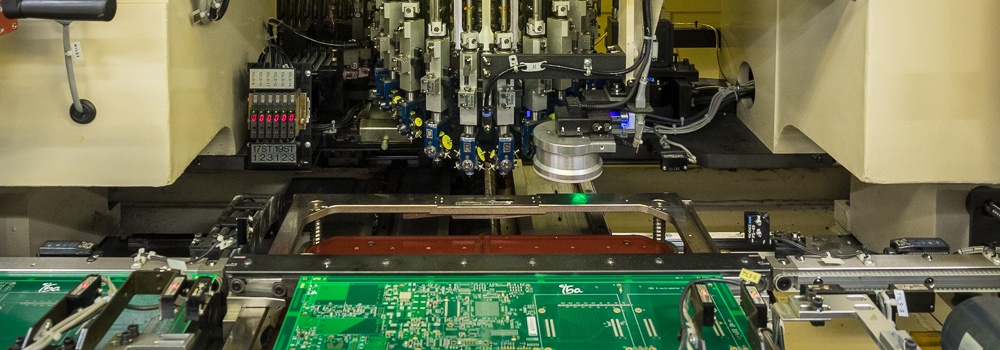

All the processes from component procurement, over SMD pick and place, automatic placement, wave soldering, testing till system/product assembly and packaging and logistics are available in house. It is up to the customer to decide which part of this supply chain he wants to use. Dekimo is not only ISO9001/2015 certified, but can offer full traceability down to manufacturer batch code, and has a 35 years knowhow as former Pioneer Automotive Electronics assembly plant